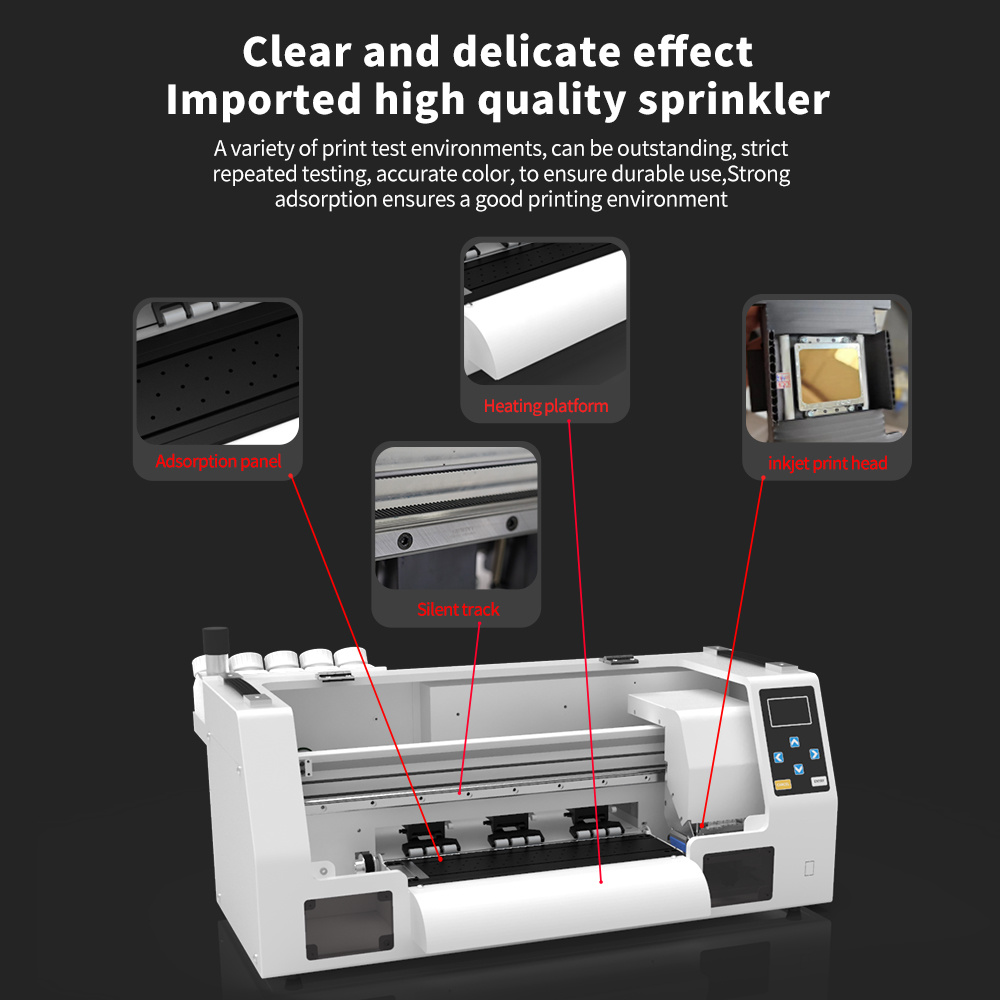

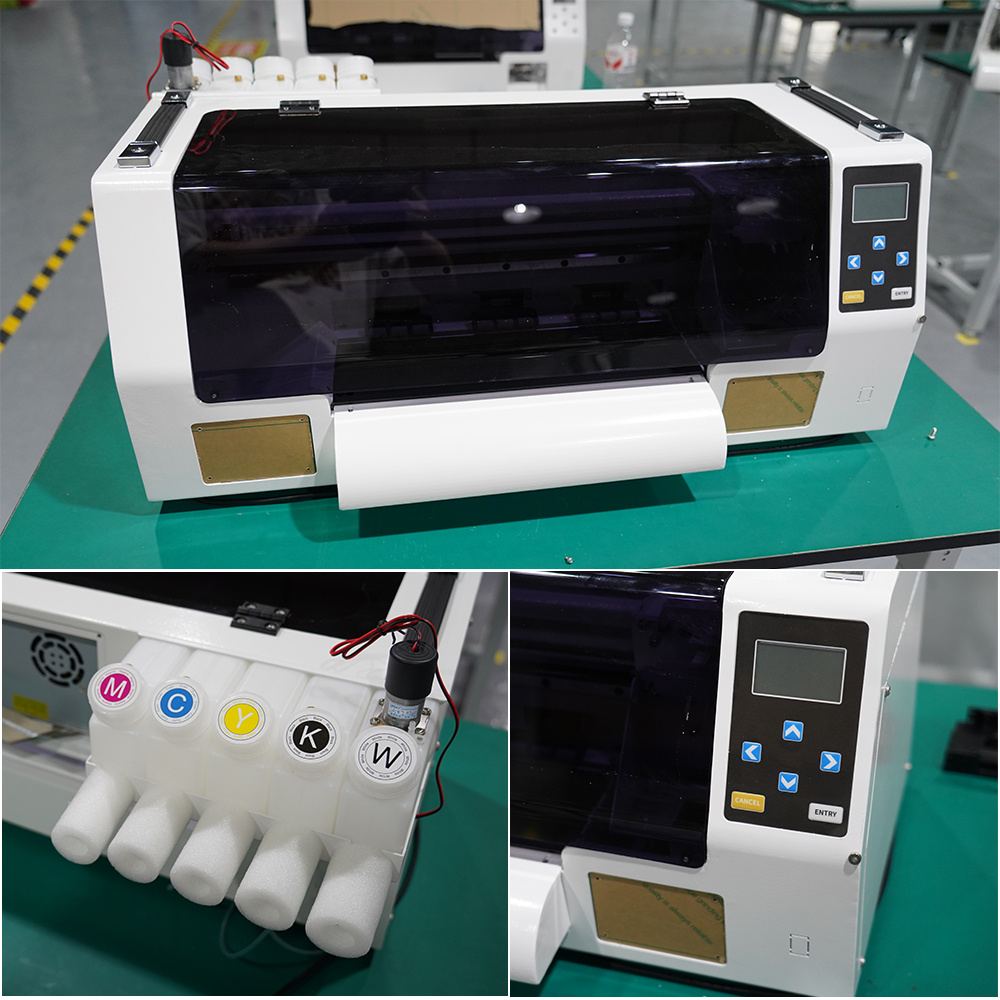

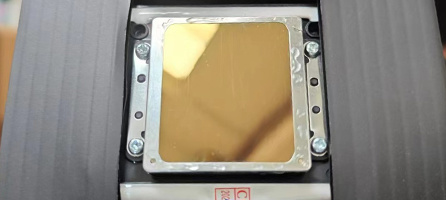

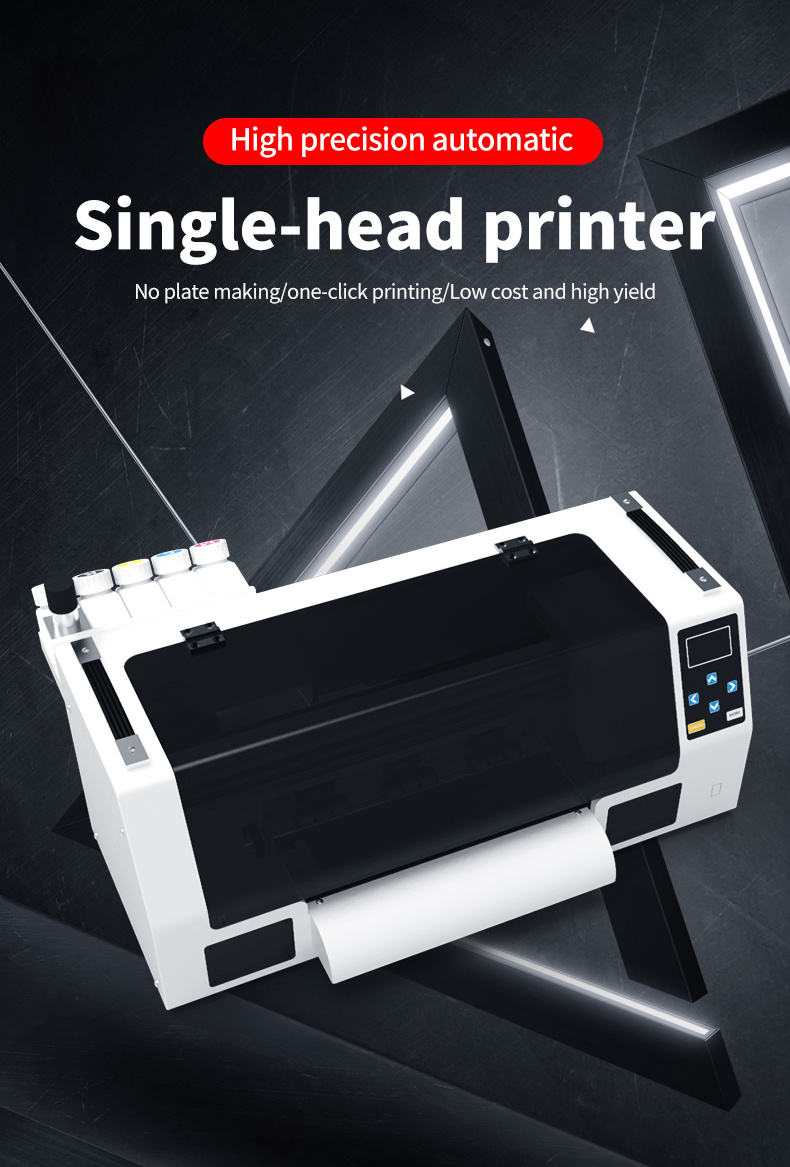

Epson original print head

The original Epson printhead technology minimizes clogging risks while maintaining optimal resolution for detailed designs

Product Detail

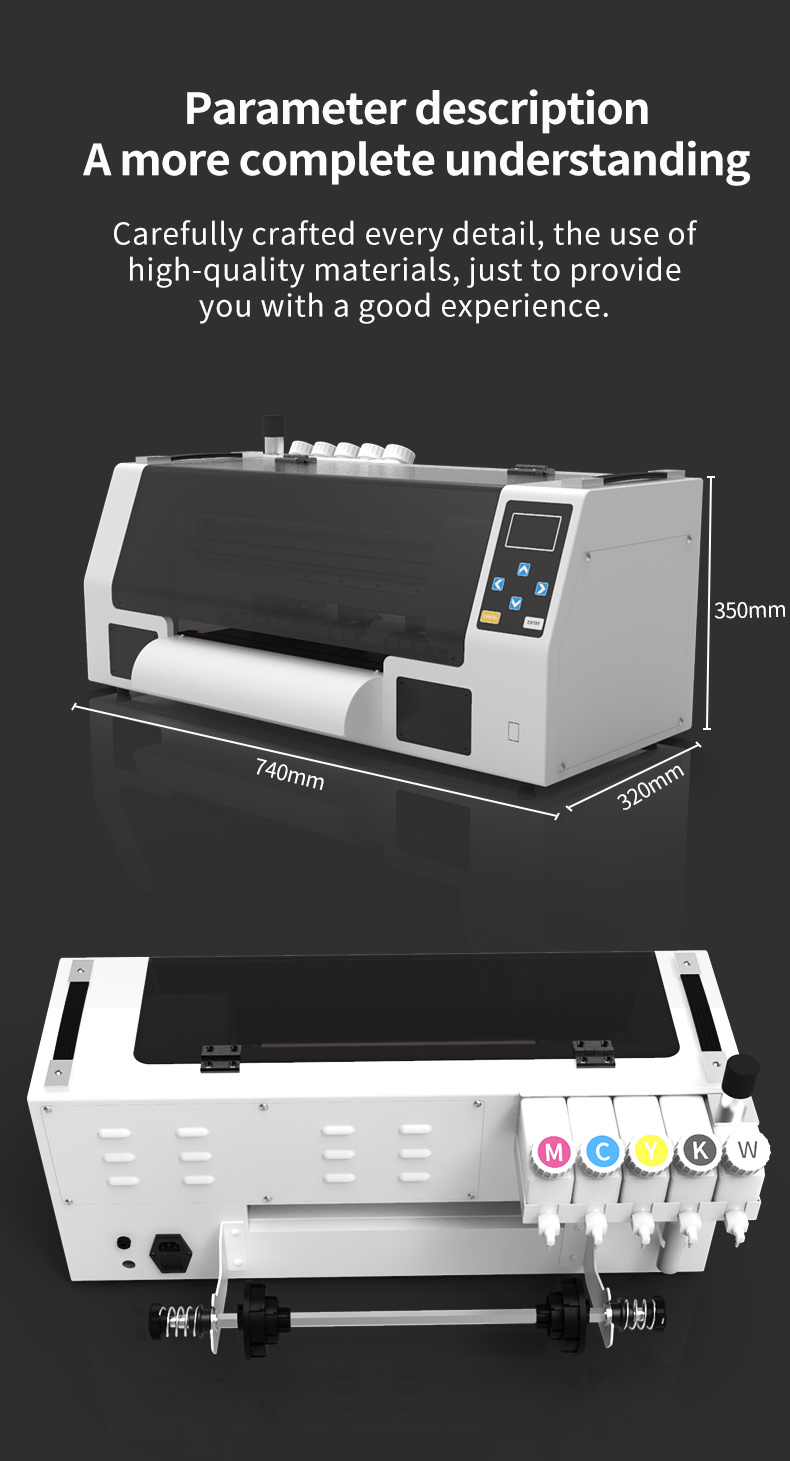

Type and quantity of nozzle | XP600 |

Printing width | 330MM/12'' |

RIP Software | MainTop, RIIN,Photoprint |

Temperature Humidity | Temperature:20-30C Humidity:45-65% |

Machine Dimension | 350*740*320cm 26KG |

Weight | 26KG |

Print Speed ↓ | |

EPS XP600 4Pass 3M/H 6Pass 1.5/H | |

FAQ

Q1: What can you buy from us?

A1: Inkjet Printer,DTF Printer,UV Printer,DTF And UV Ink,DTF Oven,Heat Melt Powder,Laminating Machine,Heat Press Machine.

Q2: How can we guarantee quality?

A2: Always a pre-production sample before mass production;Always final Inspection before shipment;

Q3: Can you provide sample test printing service? I want to see the real printing process & the printing effect.

A3: Of course you can.Please send us the picture which you want to print.We will send you the printing process, the printing effect video.

Q4.Do you support customization?

A4:Yes, customization like packaging, logo, colour, etc.

Q5: What kind of warranty service do you provide?

A5:3 year warranty (not including printhead),online tech support and service.

Q6: How to install and use Desktop DTF Printer?

A6: The machine is very simple, have been installed. Only need to connect to the computer, install the printing software, the machine and then install the ink. After purchasing the machine, our technician will contact you and send you all the instructions and videos of the installation and use.

Q7: How much is the shipping cost? How do l import the purchase?

A7:We offer door to door shipping. The printer + oven is very small, only about 0.3 cubic meters. The shipping cost to most countries is around 200-500 USD. This includes shipping, import, customs, etc.You can consult our business manager to give you specific shipping prices depending on your country location.

Q8: How do I become your agent?

A8: We have specialized in producing personalized printing equipment for 12 years.d If you buy more than 3 units of the same model at one time,you have the opportunity to become our agent. You can contact our business manager for details.

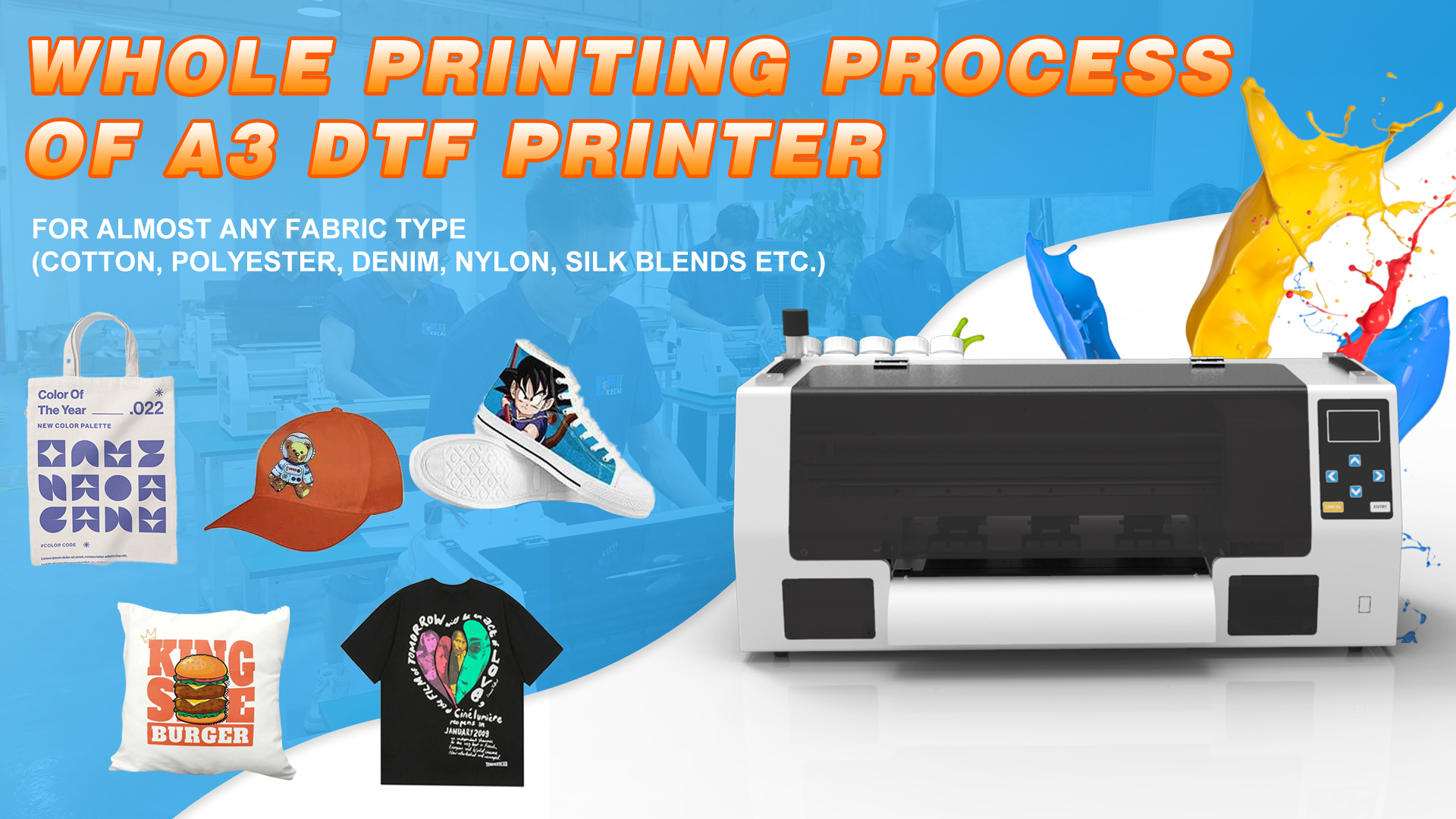

DTF (Direct-to-Film) printers have emerged as a game-changing solution in the textile printing industry, offering a versatile, cost-effective, and high-quality method for applying designs onto various fabrics. Unlike traditional printing methods, such as screen printing or direct-to-garment (DTG) printing, DTF technology allows for intricate designs, vibrant colors, and durable prints on a wide range of textile materials, including cotton, polyester, blends, and even dark or light-colored fabrics. This innovation has opened new possibilities for small businesses, custom apparel brands, and large-scale production facilities.

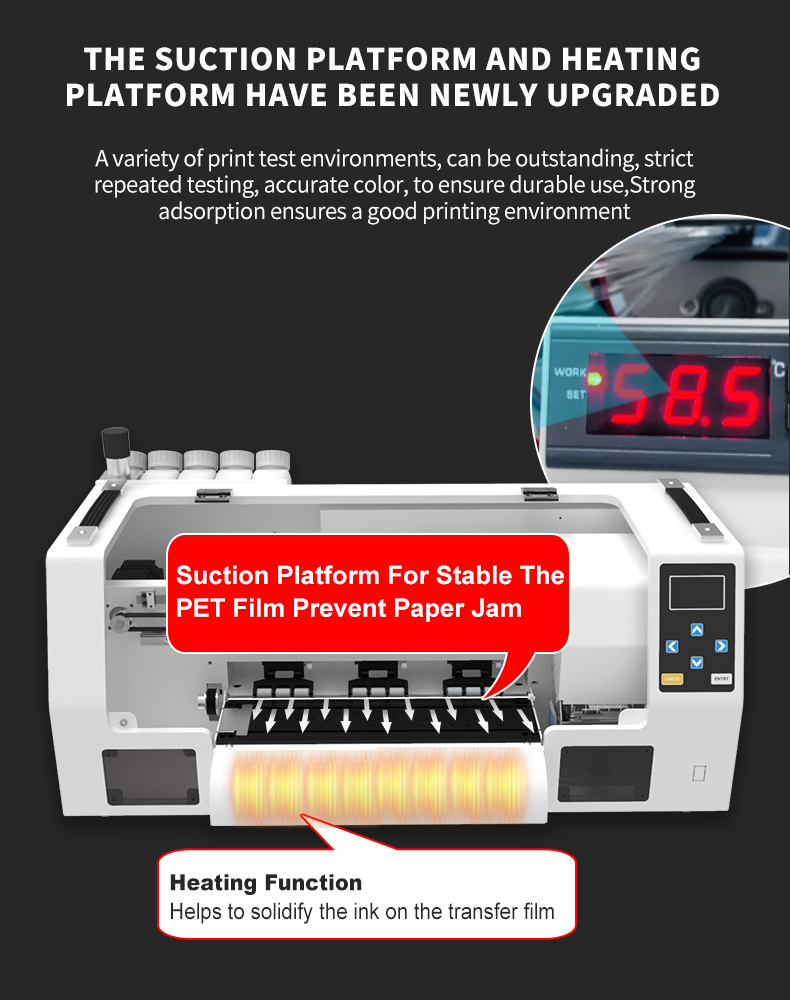

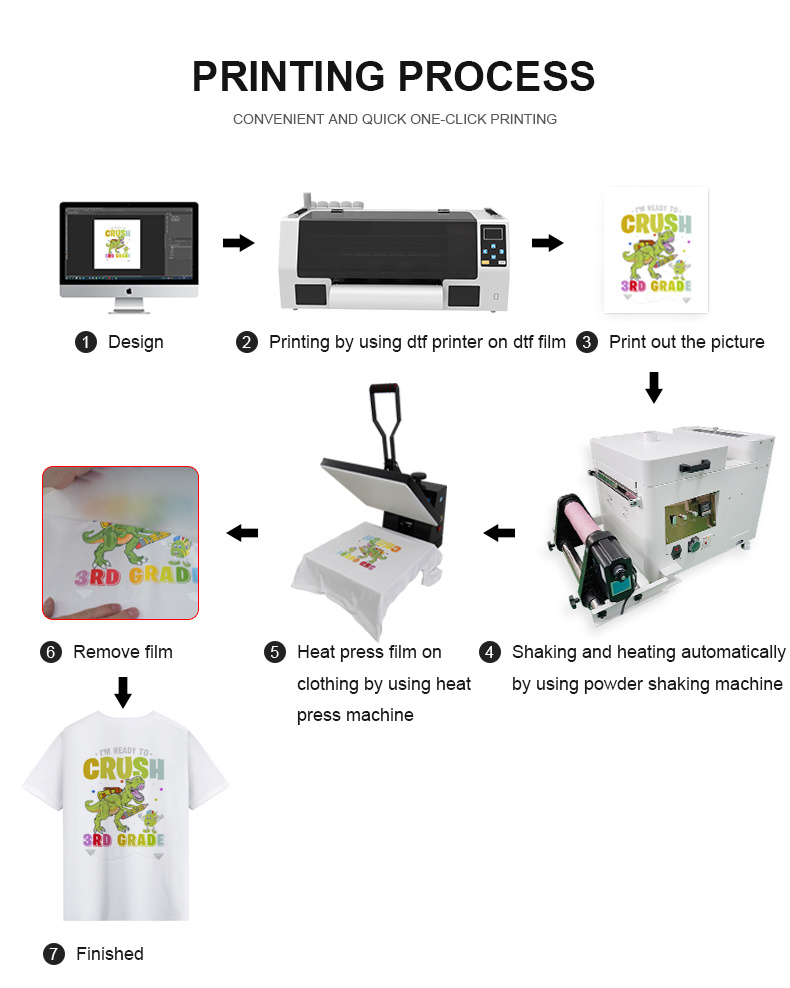

The core principle of DTF printing involves printing a design directly onto a special film using water-based inks. Once printed, a layer of adhesive powder is applied to the wet ink, ensuring that the design can bond effectively to the fabric. The printed film is then heat-transferred onto the textile using a heat press. This process allows for precise color reproduction, excellent opacity, and strong adhesion, resulting in prints that maintain their vibrancy and durability even after repeated washing.

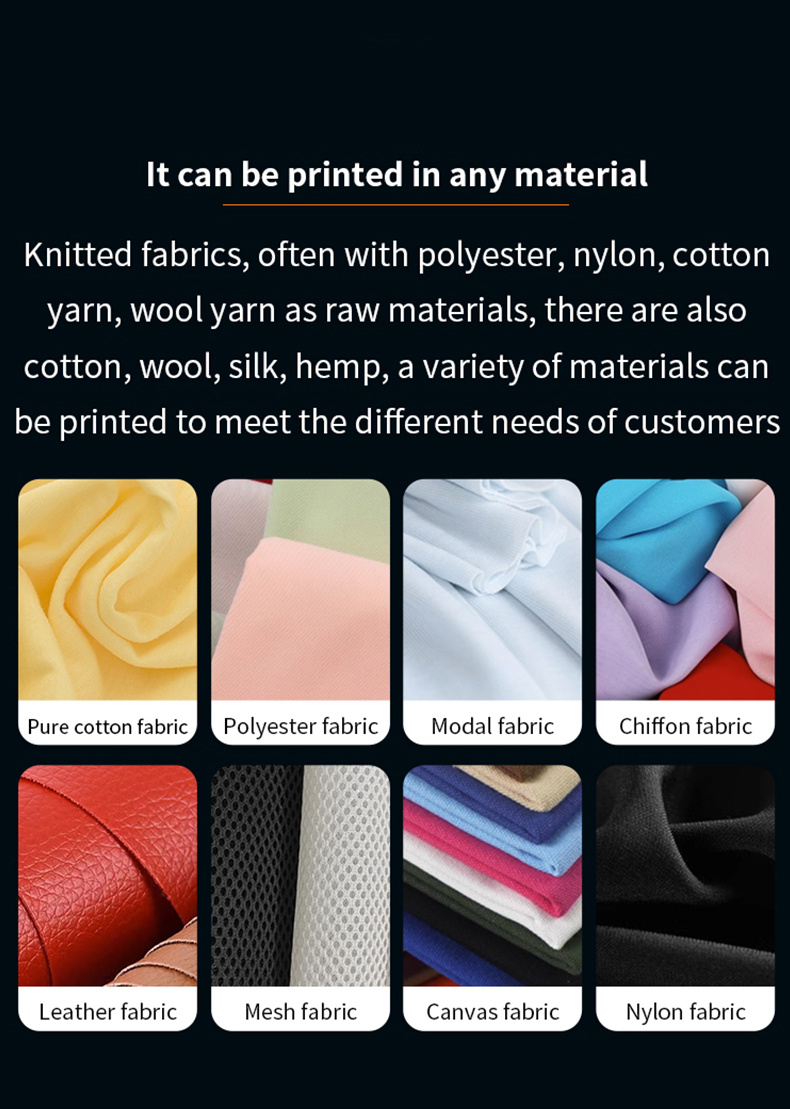

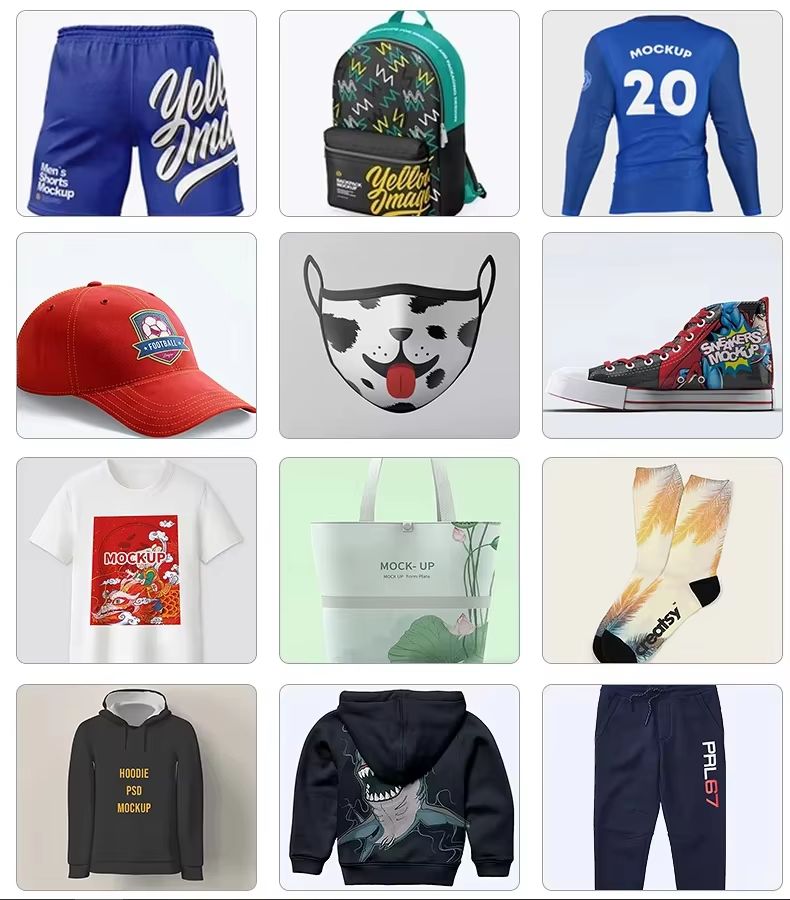

One of the major advantages of DTF printers is their versatility. They can print on virtually any type of fabric, regardless of color or texture, making them ideal for custom t-shirts, hoodies, bags, and home textiles. Unlike DTG printing, which works best on light-colored cotton fabrics, DTF printers can produce high-quality prints on dark fabrics and synthetic materials without the need for pre-treatment. This flexibility enables designers and manufacturers to experiment with different fabric types and color combinations, expanding creative possibilities and product offerings.

Efficiency and speed are also key benefits of DTF printing. Modern DTF printers are capable of producing multiple prints quickly, making them suitable for both small batch production and larger commercial runs. The process reduces setup time compared to screen printing, which requires separate screens for each color, and eliminates the limitations of fabric type or color encountered in other methods. This efficiency makes DTF printers an attractive investment for businesses looking to scale operations, reduce production costs, and deliver products to customers faster.

Another important aspect of DTF printing is the quality and durability of the final product. The prints produced by DTF printers are highly detailed, allowing for sharp lines, fine text, and complex graphics. The adhesive powder ensures strong bonding to the fabric, resulting in prints that are resistant to cracking, peeling, or fading. This durability is particularly valuable for products intended for daily use, commercial merchandise, or promotional items that need to withstand frequent washing and wear.

Ease of use and maintenance are additional advantages of DTF printers. Most modern machines come with user-friendly software that allows for precise control over colors, print size, and placement. The workflow—from designing to printing and transferring—is straightforward, making it accessible to small business owners, hobbyists, and professional print shops alike. Moreover, DTF printers require minimal pre-treatment or post-treatment of fabrics, reducing labor and material costs while simplifying the production process.

Environmental considerations are also a factor in the growing popularity of DTF printers. Water-based inks used in DTF printing are less harmful to the environment compared to solvent-based alternatives, and the process generates minimal waste. By using films and powders efficiently and reducing the need for multiple prints or corrections, DTF technology contributes to a more sustainable approach to fabric printing.

In addition to business applications, DTF printing supports creativity and customization. Artists, designers, and entrepreneurs can create unique, personalized products for niche markets, from custom apparel to limited-edition merchandise. The technology supports full-color prints, gradients, photographic images, and intricate patterns, enabling high levels of artistic expression and innovation.

In conclusion, DTF printers are transforming the textile printing industry by offering a versatile, high-quality, and efficient solution for producing durable, vibrant designs on a wide variety of fabrics. Their ability to print on dark and light fabrics, combined with ease of use, speed, and environmental benefits, makes them an attractive choice for businesses, designers, and hobbyists alike. By integrating DTF technology into production workflows, users can expand creative possibilities, improve operational efficiency, and deliver superior printed products that stand out in a competitive market.

KECAI 12 Inch XP600 A3 DTF Printer Direct to Film Printer

Product Features ■DTF printer, also known as Direct to Film printer, is a digital clothing printing device mainly used to directly print design patterns onto PET film. ■The consumables used in this printer include DTF transfer film, DTF hot melt powder, and DTF ink. ■The process of DTF printing includes printing the design pattern onto a PET film, evenly sprinkling hot melt powder, undergoing high-temperature melting and drying treatment, and finally attaching the pattern on the PET film to various types of clothing or other items, such as luggage, shoes, hat, bag etc. through a hot press. ■DTF printers are suitable for a variety of clothing materials, including pure cotton, polyester, nylon, processed leather, polyester fabrics, 50/50 blend fabrics, and fabrics of different colors.

Category:

Key Words:

KECAI 12 Inch XP600 A3 DTF Printer Direct to Film Printer

dtf printer

Equipment Cases