Hoson motherboard

Big brand motherboard, Stable output and printing

Product Detail

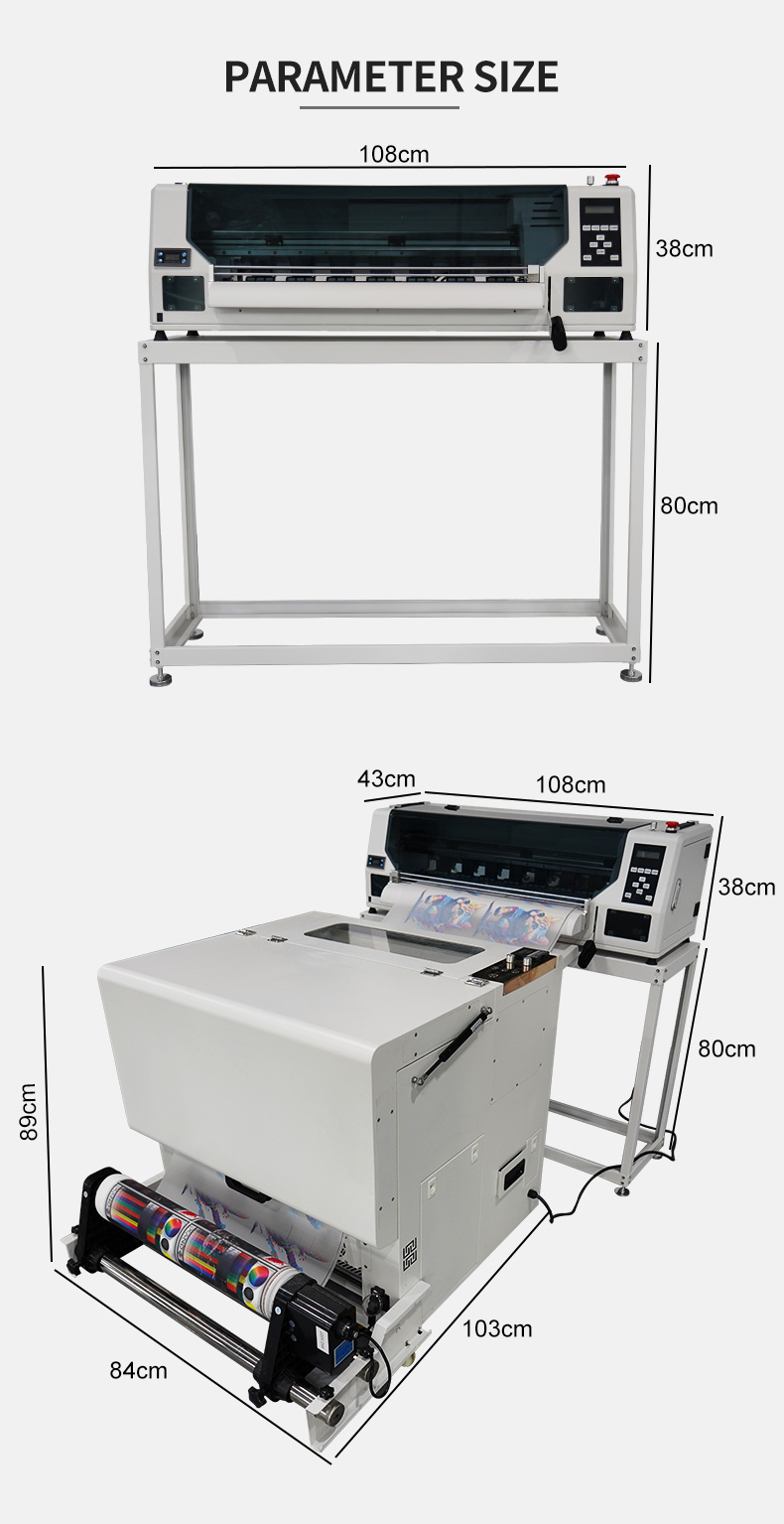

Product name | A1 DTF Printer | |||

Type and quantity of print head | 2pcs Epson xp600 | 2pcs Epson i1600 | 2pcs Epson i3200 | |

Printing speed | 6Pass 4m2/H 8Pass 2m2/H | 6Pass 6M/H 8Pass 4M/H | 4Pass 12M/H 6Pass 8M/H | |

Available width | 600MM | |||

Ink color | CMYK+W | |||

Ink type | DTF ink | |||

Print media | DTF printing film | |||

RIP software | Maintop | |||

Printer advantages | White ink mixing system and white ink circulation system | |||

Pet film enter and retract system | ||||

Updated motor for constantly printing | ||||

One-click automatic cleaning system | ||||

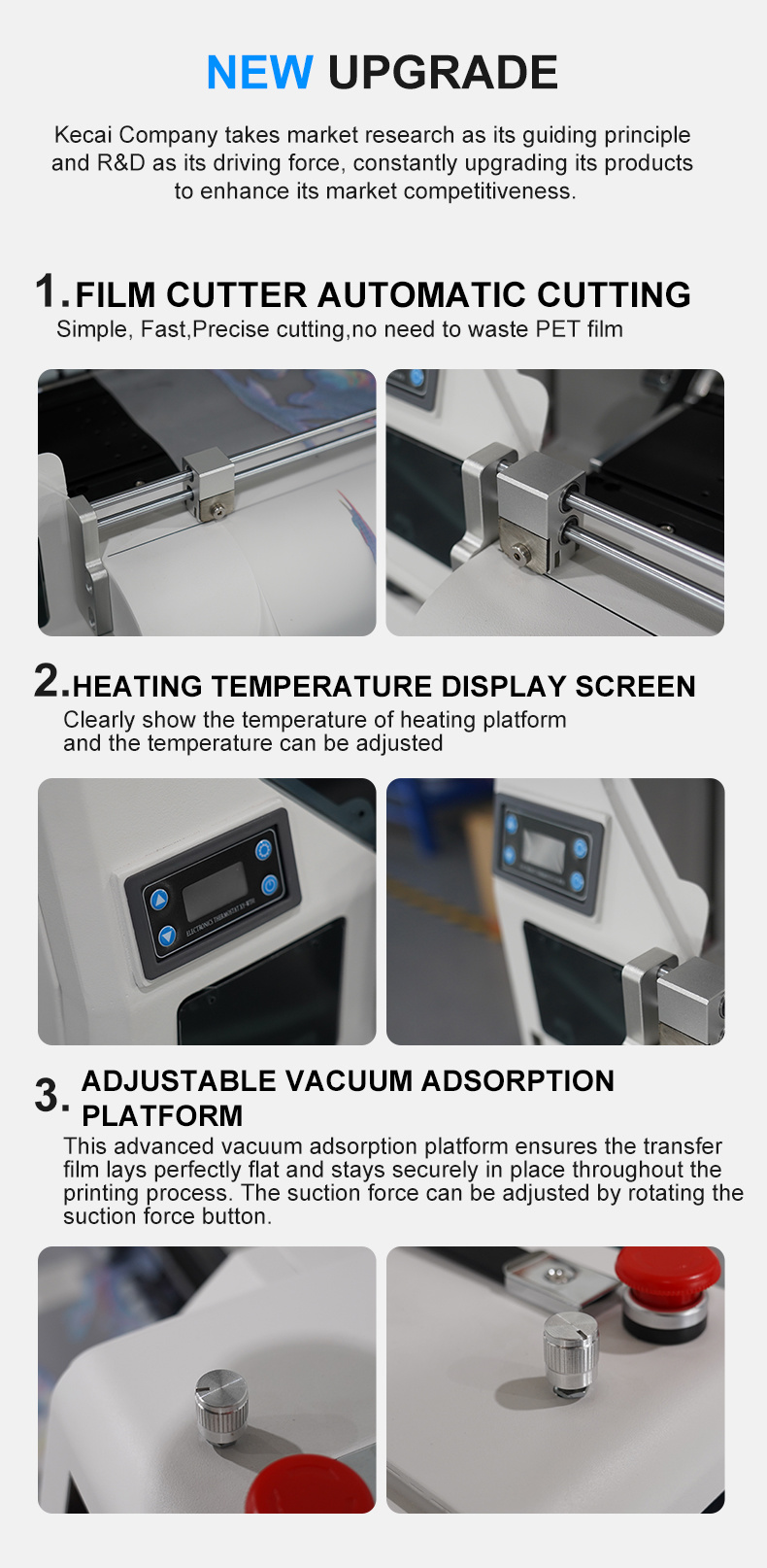

Film cutter | ||||

Vacuum suction platform | ||||

Heating platform | ||||

Motherboard | Hoson | |||

Temperature Humidity | Temperature:20-30°C Humidity:45-65% | |||

Ink Supply System | Negative CISS | |||

Voltage | 110V-220V 50/60Hz | |||

Picture format | Bmp, TIF, Jpg, Pdf etc. | |||

Feeding and take-up | Auto roll-to-roll | |||

Q1: What can you buy from us?

A1: DTF Printer,UV Printer,DTF And UV Ink,DTF Oven,Heat Melt Powder,Laminating Machine,Heat Press Machine.

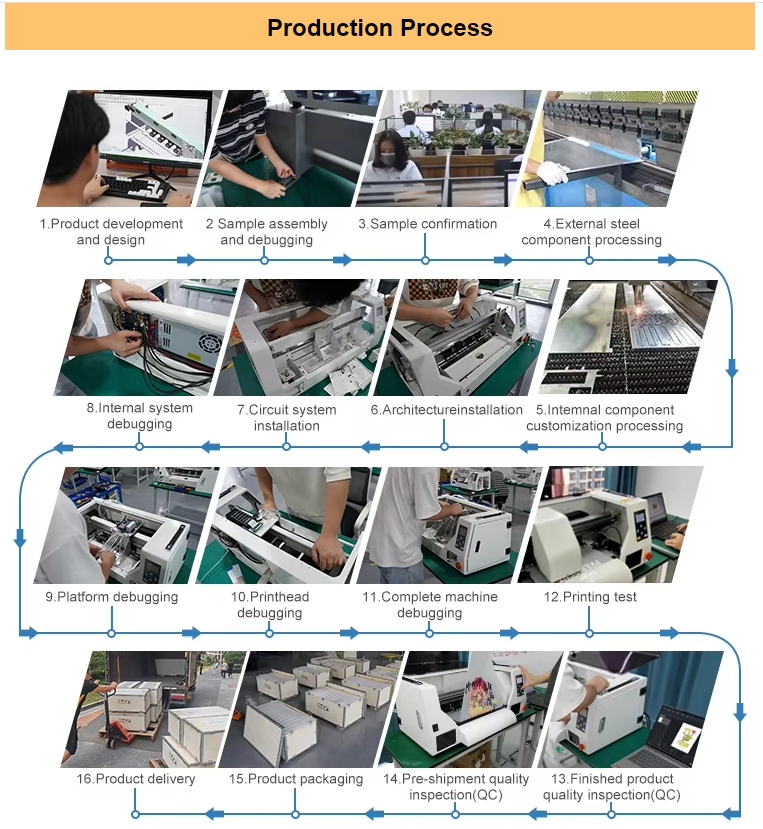

Q2: How can we guarantee quality?

A2: Always a pre-production sample before mass production;Always final Inspection before shipment;

Q3: Can you provide sample test printing service? I want to see the real printing process & the printing effect.

A3: Of course you can.Please send us the picture which you want to print.We will send you the printing process, the printing effect video.

Q4.Do you support customization?

A4:Yes, customization like packaging, logo, colour, etc.

Q5: What kind of warranty service do you provide?

A5:1 year warranty (not including printhead),online tech support and service.

Q6: How to install and use Desktop DTF Printer?

A6: The machine is very simple, have been installed. Only need to connect to the computer, install the printing software, the machine and then install the ink. After purchasing the machine, our technician will contact you and send you all the instructions and videos of the installation and use.

Q7: How much is the shipping cost? How do l import the purchase?

A7:We offer door to door shipping. The printer + oven is very small, only about 0.3 cubic meters. The shipping cost to most countries is around 200-500 USD. This includes shipping, import, customs, etc.You can consult our business manager to give you specific shipping prices depending on your country location.

Q8: How do I become your agent?

A8: We have specialized in producing personalized printing equipment for 12 years.d If you buy more than 3 units of the same model at one time,you have the opportunity to become our agent. You can contact our business manager for details.

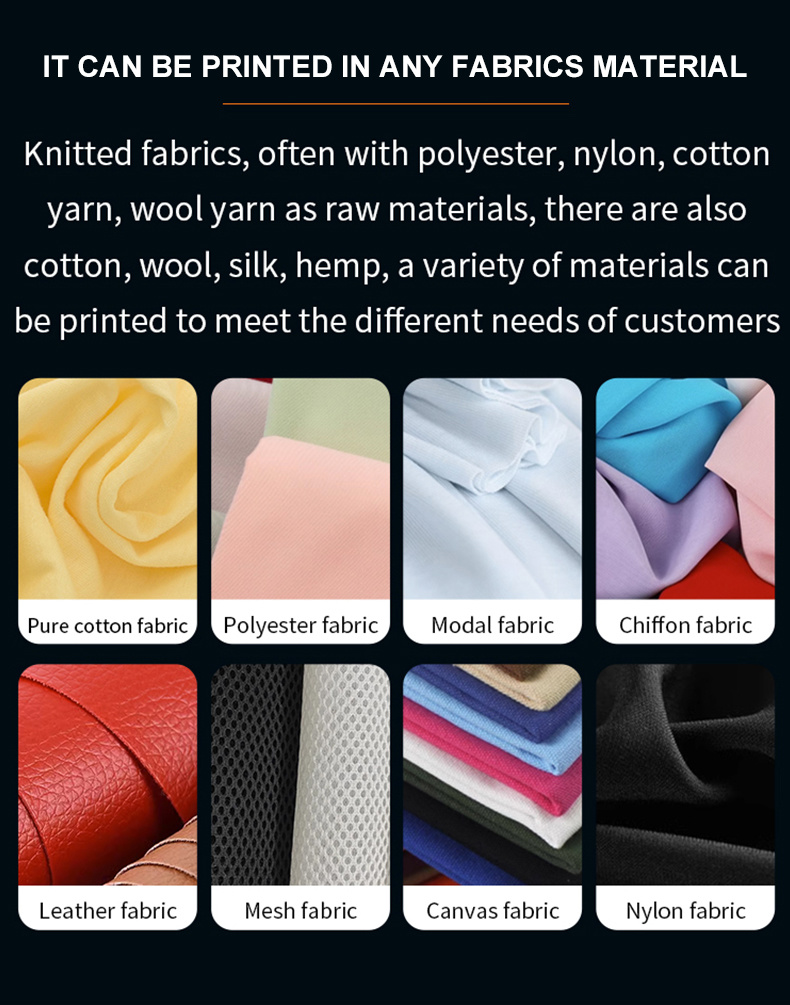

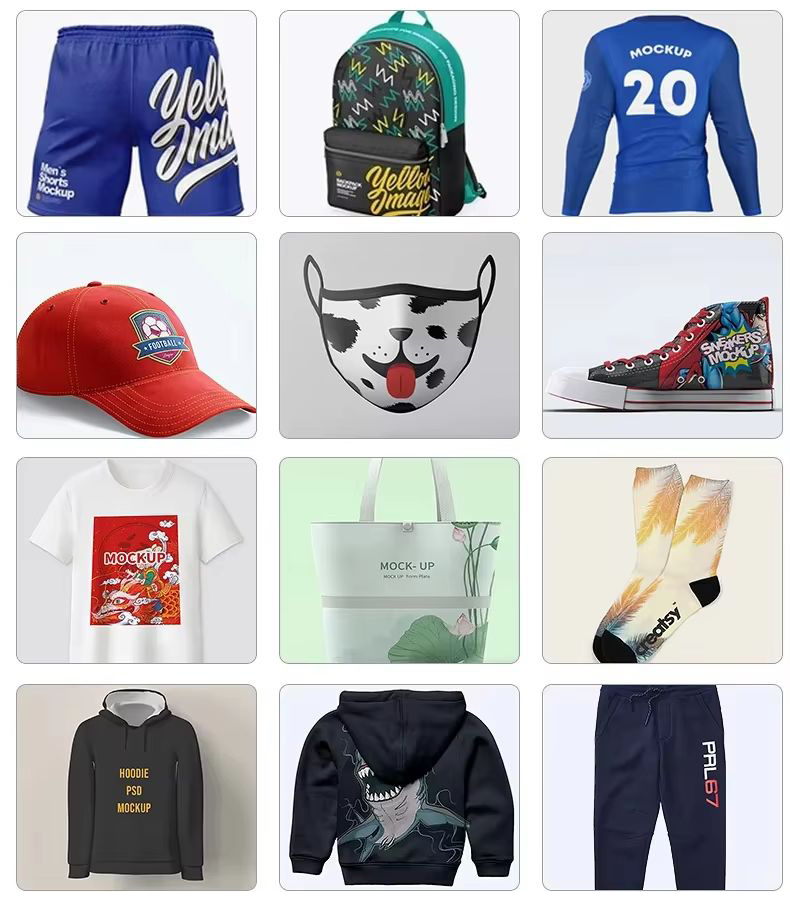

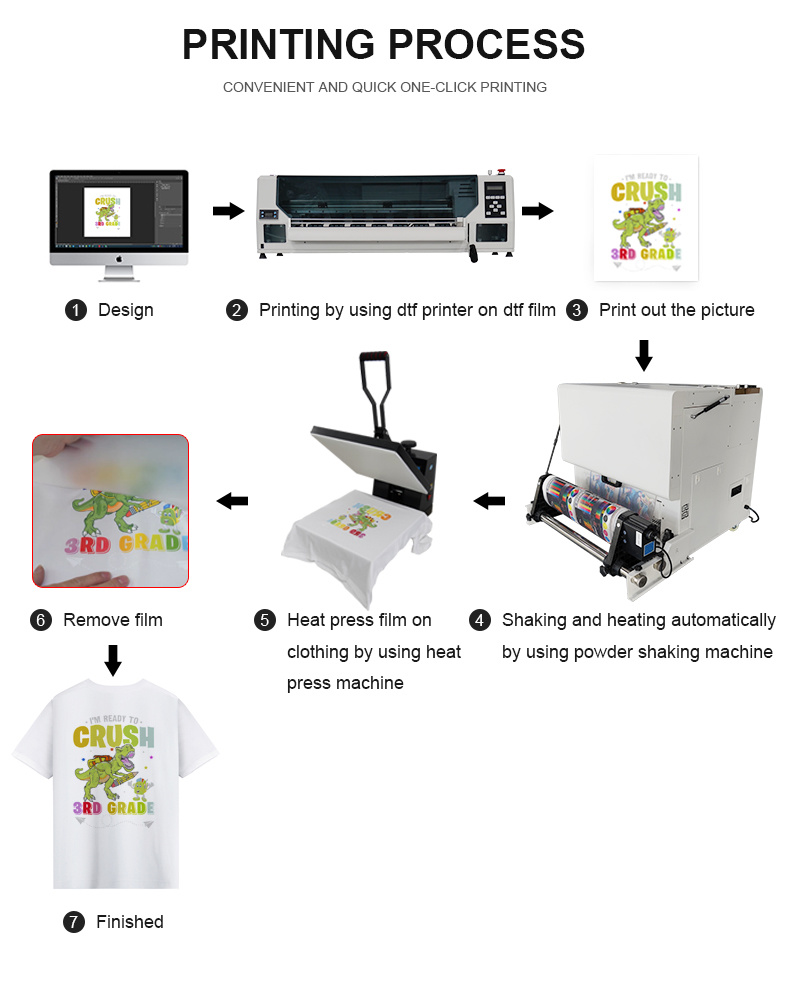

DTF (Direct-to-Film) film printing machines have revolutionized the textile and custom apparel industry by providing an efficient, versatile, and high-quality printing solution. Unlike traditional methods, DTF printing allows designs to be printed directly onto special transfer films, which are then heat-pressed onto fabrics, including cotton, polyester, blends, and other materials. This technology has gained significant popularity due to its vibrant colors, detailed resolution, and ability to produce durable prints without the need for pre-treatment or extensive setup.

A key advantage of DTF film printing machines is their versatility. They support a wide range of textile materials and can produce intricate designs with gradients, photographic images, and fine details that are challenging for traditional screen printing or heat transfer methods. DTF machines use specialized inks and adhesive powders to ensure that the printed designs adhere firmly to the fabric after heat pressing. This process results in prints that are flexible, soft to the touch, and resistant to cracking, fading, or peeling, even after multiple washes.

Efficiency is another critical benefit. DTF printing machines are designed for high-speed operation, allowing manufacturers and custom apparel businesses to produce large quantities of garments quickly and consistently. Automated feeding systems, precision inkjet heads, and reliable curing units ensure that each print maintains high quality with minimal errors or inconsistencies. This efficiency reduces production time and labor costs, making DTF an attractive solution for small businesses, startups, and large-scale production facilities alike.

DTF film printing machines also offer cost-effectiveness. Unlike screen printing, which requires separate screens for each color, DTF printing allows full-color designs to be produced in a single pass, reducing material waste and setup costs. Additionally, since DTF prints can be applied to fabrics without pre-treatment, it eliminates the need for extra chemicals or preparation steps, further streamlining the production process and lowering operational costs.

Color quality and print durability are major advantages of DTF film printing. The machines use high-quality pigment or dye-based inks that produce vibrant, saturated colors with sharp details. After the design is transferred to the fabric using heat and pressure, the prints are resistant to fading, stretching, and cracking, even after repeated washing. This makes DTF prints ideal for apparel, promotional products, home textiles, and other items where longevity and aesthetic appeal are important.

Customization and flexibility are essential features of DTF printing. Businesses can produce one-off custom designs, limited-edition apparel, or bulk orders with equal ease. The digital nature of the process allows for easy modification of designs, logos, or text without the need to create new screens or templates. This capability is particularly valuable for on-demand printing services, e-commerce apparel businesses, and personalized gift items.

DTF film printing machines are equipped with advanced technological components to ensure precision and reliability. High-resolution inkjet print heads, adjustable print speed settings, and precise temperature-controlled curing systems enable consistent, high-quality output. Many machines also include features such as automatic film feeding, powder application, and digital control panels for easy operation and monitoring. Some advanced models integrate with software that allows for color management, design adjustments, and workflow optimization, enhancing overall production efficiency.

Environmental considerations are also addressed by modern DTF printing technology. Many machines use eco-friendly inks and adhesives that comply with environmental regulations, reducing the environmental impact of production. Since the process generates minimal waste compared to traditional printing methods, it contributes to a more sustainable manufacturing workflow. Additionally, DTF printing reduces the need for multiple production steps, conserving energy and materials.

Maintenance and reliability are key aspects of DTF film printing machines. With proper care, these machines offer long-term operation with minimal downtime. Regular cleaning of print heads, monitoring of ink levels, and periodic servicing ensure that the machine continues to produce consistent, high-quality prints. The design of these machines often allows for easy replacement of parts and components, ensuring minimal disruption to production.

In summary, DTF film printing machines provide a comprehensive, efficient, and high-quality solution for textile and apparel printing. They offer versatility in fabric types, precise and vibrant printing, cost-effective production, and durability for finished products. Their ability to produce customized designs quickly and efficiently makes them ideal for modern printing businesses, from small custom apparel shops to large-scale manufacturing facilities. With advanced technological features, environmental considerations, and reliable performance, DTF film printing machines have become an essential tool for any business looking to excel in the competitive textile and apparel market.

KECAI A1 60CM Heat Transfer Printing Pet Film DTF Printer Machine

Product Features ■60cm (24 inches) - Capable of printing designs up to 60cm wide. Ideal for medium-large apparel, bags, or multiple smaller designs printed side-by-side on a single film sheet. ■Mid-Volume Production: Suitable for small-to-medium businesses, print shops, or custom apparel producers needing efficient batch production. ■Lower Setup Cost (vs. DTG/Screen Printing): Requires no screens, minimal setup per job, and no pre-treatment for garments. ■Economical for Short Runs: Ideal for small batches or one-offs without high setup fees.

Category:

Key Words:

KECAI A1 60CM Heat Transfer Printing Pet Film DTF Printer Machine

60 cm dtf printer for custom apparel

dtf film printing machine

Equipment Cases