Rise and Trend Prospects of DTF Technology

2025-06-16

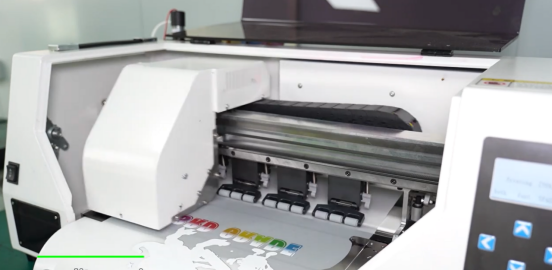

Since its inception, DTF technology has sparked a craze in the industry in just twenty years.

The popularization and improvement of DTF technology have led to rapid market expansion and intensified competition. However, it is precisely this rapid growth that makes us pay more attention to the future development trend of DTF, especially its popularity and profit potential.

The rapid development of DTF technology: data and trends

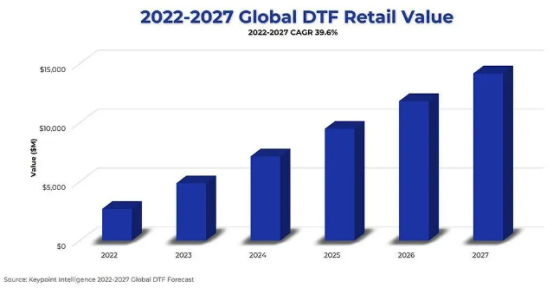

According to the latest report from Keypoint Intelligence, the printing volume of DTF has achieved astonishing growth in recent years.

In 2022, the printing volume of DTF is expected to be around 190 million square meters, and by 2027, this number is expected to climb to around 1 billion square meters. From a value perspective, the retail value of the DTF market in 2022 is expected to be $2.78 billion, and this number is projected to surge to $14 billion by 2027.

This growth momentum is not only reflected in the increase of printing volume, but also in the rapid expansion of DTF device deployment.

The report points out that in 2022, the deployment of DTF devices accounted for approximately 44.5% of all DTF, direct injection, and transfer printing device deployment, and by 2027, this proportion is expected to climb to 64.4%. This means that DTF technology is rapidly dominating the market.

In addition, there will be approximately 9082 DTF devices in operation worldwide in 2022, and by 2027, this number is expected to approach 15000. These devices are mainly dual head machines, while four head devices occupy about a quarter of the market share.

Why is DTF so popular

The rapid rise and widespread popularity of DTF technology in a short period of time are mainly due to its various advantages.

Easy to learn and master

The printing process is very similar to printing on paper, which allows printers to quickly get started. DTF technology can also be completed in a smaller space and is almost applicable to enterprises of all sizes. This flexibility and ease of operation make DTF technology the preferred choice for many enterprises.

Fast printing speed and high turnover efficiency

After the film is printed, it can be stored until it needs to be transferred. This not only allows suppliers to prepare their work in advance, but also eliminates the need for double white or CMYK printing when using other printing methods, saving time and costs.

Significant cost-effectiveness

Although films and powders require additional costs, overall, DTF is often one of the most cost-effective processes. This enables suppliers of all sizes to benefit from it and achieve maximum economic benefits.

Wide range of applications

DTF technology can perfectly handle ordinary clothing such as T-shirts, hoodies, and sportswear, as well as interior decoration. This wide range of applications makes DTF technology highly competitive in the market.

Compared to DTG, DTF technology has certain advantages. For example, DTF has faster printing speed, lower cost, and wider application range. This makes DTF technology more competitive in the market. However, we should also recognize the challenges and opportunities that DTF technology faces. Only through continuous innovation and improvement can DTF technology maintain its leading position in the future market.

More Information

Rise and Trend Prospects of DTF Technology

2025-06-16

How to identify a good UV flatbed printer

2025-06-16